Skontaktuj się z nami

Telefon

Polska

26.01.2022

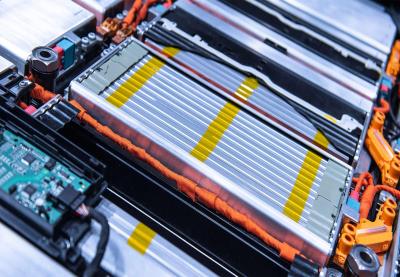

How KVT-Fastening helps the manufacturing of the EV battery pack

When it comes to building an electric vehicle, the battery pack and the motor lie in the heart of the manufacturing, which is accountable for vital parameters such as speed, mileage, and torque. While using a powerful motor is no big deal, the major challenge lies in the design of a battery pack that could supply enough current for the motor for a long time while withholding its lifespan. In order to manage the voltage and current demand, an EV battery pack is composed of numerous cells for a single car. The joining of several battery cells in a module, the busbar, the cooling system, the battery frame, and the housing all require robust and reliable fastening elements.

PEM self-clinching studs and self-clinching nuts for stainless steel are currently used in the EV battery pack

Our customer, a leading electric vehicle manufacturer, discovered the limitation in their design with the self-clinching fasteners during one of the KVT webinars at the last stage of the design phase. Our experts were therefore contacted for the consultancy.

As our product manager of self-clinching technology, Klemens Freyinger, visited our customer, our suggestion of using the PEM self-clinching studs and self-clinching nuts for the busbar, BMS holder, and the inverter mount brought substantial progress in the design development of the battery pack. The customer was benefiting significantly from the know-how and experience of our experts. Since then, KVT-Fastening has been serving as a fastening consultant for the customer from the design phase on.

The challenge: geometric limitation and material compatibility

Klemens Freyinger: “The most challenging part of the EV battery pack manufacturing is that it is a new field on the market, and no one knows what will happen in 5 years”. While the beginning of the electric vehicle can be traced back to the 1800s, the real mass-produced electric vehicle started just at the beginning of the 21st century, and it was not until around 10 years ago that car manufacturers have plunged into the research and development of the battery pack. The field is still new and fast-changing, and the fastening know-how for the battery pack has not prevailed on the market yet.

Klemens Freyinger: “The most challenging part of the EV battery pack manufacturing is that it is a new field on the market, and no one knows what will happen in 5 years”. While the beginning of the electric vehicle can be traced back to the 1800s, the real mass-produced electric vehicle started just at the beginning of the 21st century, and it was not until around 10 years ago that car manufacturers have plunged into the research and development of the battery pack. The field is still new and fast-changing, and the fastening know-how for the battery pack has not prevailed on the market yet.

The technical challenge of the fastening in the battery pack is the geometric limitation and the compatibility of different materials. While choosing the type of fastener is usually not difficult, the consideration of the geometrics of a specific fastener and the space limitation in the battery pack is not always apparent for the design engineers. Moreover, the compatibility of different materials between the fastener and the battery pack component has a critical impact on the battery lifetime. In the current industry standard, the difference in electric potential between them should be a maximum of 0.6 volts to avoid galvanic corrosion. As a specialist in fastening solutions, we consider every little detail when it comes to fastening design. This is when the fastening know-how of KVT-Fastening could significantly help.

Benefit from the holistic engineering services from KVT-Fastening

To help our customer optimize the design of the battery pack, we suggested suitable fasteners, executed the push-out and torque-out tests for the selected fasteners, and implemented an on-site Tech-Day at the customer site for sharing the know-how. Since then, we stay with the customer for their further projects and offer our consultancy when it comes to fastening and assembly challenges.

Do you have any uncertainty about the fastening in your project?

Would you like to be advised by our experts?

More information about the fastening technology in EV sector: Download EV Brochure

We are happy to advise you professionally and free of charge to find the best fastening solution for your projects and manage your fastening challenge together with you.